Blister Packaging Machine Series

Blister Packaging Machine Series

- DPP-260 Flat-plate Blister Packing Machine

- DPH-260 Roll-plate Blister Packaging Machine

- DPR-320G aluminum-plastic-aluminum equipment

- DPH-400H Roller Plate Blister Packaging Machine

- DPH-260L Roller Plate Blister Packaging Machine

- DPH-400K roller plate blister packaging machine

- DPH-260L roller plate blister packaging machine

- DPP-260 Flat-plate Blister Packing Machine

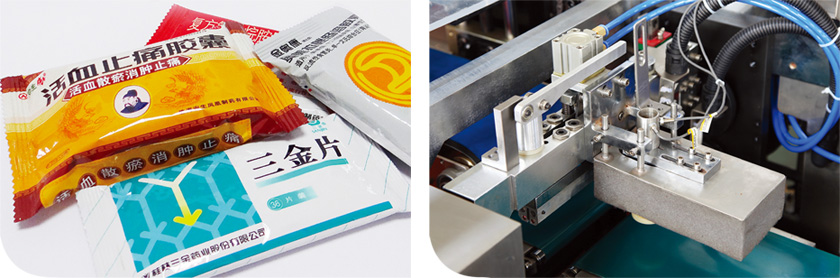

Pillow-type Packing Machine Series

Pillow-type Packing Machine Series

- DZB-250D Multifunctional Pillow-Type Automatic Packing Machine

- DWB-500 Reciprocating Pillow-Type Packaging Machine

- DWB-500G High Speed Reciprocating Pillow Type Packing Machine

- DWB-500K High Speed Reciprocating Pillow Type Packing Machine

- DZB-250/400 Multifunctional Pillow Block Fully Automatic Packaging Machine

- DWB-250C/400C/600C多功能枕式版塊全自動(dòng)包裝機(jī)

- DWB-500H High-speed Reciprocating Pillow Packaging Machine

- DWB-500H High-speed Reciprocating Pillow Packaging Machine

- HTZ-350S/450S High speed pillow packing machine

- DZB-250D/400D multi-functional pillow section automatic packaging machine

- DZB-250D Multifunctional Pillow-Type Automatic Packing Machine

Fully Automatic Cartoning Machine

Fully Automatic Cartoning Machine

High Speed Transparent Film Three-dimensional Wrapping Machine

High Speed Transparent Film Three-dimensional Wrapping Machine

Horizontal Automatic More Usage Packing Machine

The Speciality Manufacturer of Medical Supplies Packing Machine

Auxiliary device

Auxiliary device

Production line packaging

Production line packaging

This machine is our company scientific research personnel based on DWB-500 reciprocating pillow packaging machine, adopt all servo motor control structure and packing speed improvement and increase the number of detection and elimination, fault diagnosis, alarm and shutdown, remote control functions, which greatly improves the production efficiency, reduce personnel and production cost.

-

1.Touch screen control, simple operation.

-

2.The length of the bag of arbitrary choice, automatic adjustment, fast, accurate.

-

3.Reciprocating end sealing mechanism, servo motor drive firmer sealing, sealing cutting knife without loss.

-

4.Drug aluminum plate servo feeding, one to five plate touch screen set arbitrarily.

-

5.The machine with photoelectric color code tracking, benchmarking the normal operation, in the operation process of bag material joint errors and synchronization failure on the plate, can be set the number of alarm shutdown.

-

6.The PLC module, six groups of temperature control, temperature control, temperature display, on the screen.

-

7.Packaging film tape joint automatic detection and rejection.

-

8.Coder Machine leakage automatic detection and rejection.

-

9.Medicine plate missing, automatically detect rejection.

-

10.Film lack alarm shutdown.

-

11.Menu functions of memory (with various parameters stored in different packagingproducts).

-

12.Ethernet Remote control, can modify the program.

|

Production Capacity |

60-135 Bags/min(Vary with different specifications) |

|

Film Width |

(Max) 450mm |

|

Cut Off Length |

80-300mm |

|

Product Size |

(Length)60-200mm,(Width)35-200mm,(Height)5-55mm |

|

Weight |

(about)1300kg |

|

Rated Voltage |

AC220V/50Hz |

|

Total Power |

5.25kw |

|

Overall Dimension |

(L×W×H) 3750×1200×1700mm |

Note: The products of our company may always be updated, and are subject to change without notice (the real products shall prevail).