Blister Packaging Machine Series

Blister Packaging Machine Series

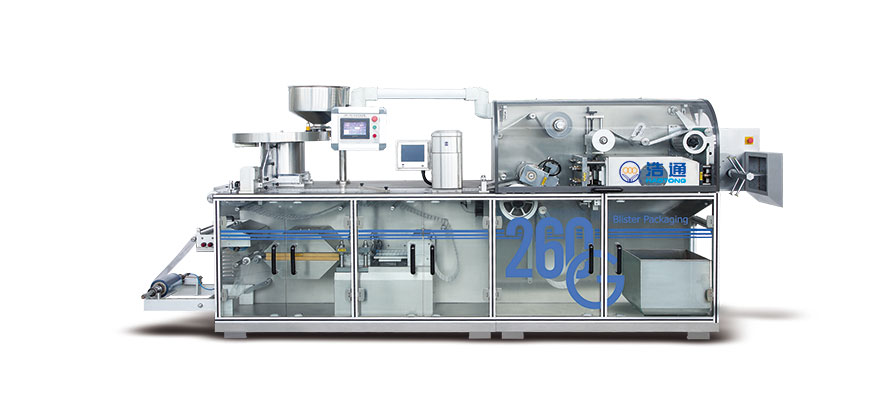

- DPP-260 Flat-plate Blister Packing Machine

- DPH-260 Roll-plate Blister Packaging Machine

- DPR-320G aluminum-plastic-aluminum equipment

- DPH-400H Roller Plate Blister Packaging Machine

- DPH-260L Roller Plate Blister Packaging Machine

- DPH-400K roller plate blister packaging machine

- DPH-260L roller plate blister packaging machine

- DPP-260 Flat-plate Blister Packing Machine

Pillow-type Packing Machine Series

Pillow-type Packing Machine Series

- DZB-250D Multifunctional Pillow-Type Automatic Packing Machine

- DWB-500 Reciprocating Pillow-Type Packaging Machine

- DWB-500G High Speed Reciprocating Pillow Type Packing Machine

- DWB-500K High Speed Reciprocating Pillow Type Packing Machine

- DZB-250/400 Multifunctional Pillow Block Fully Automatic Packaging Machine

- DWB-250C/400C/600C多功能枕式版塊全自動(dòng)包裝機(jī)

- DWB-500H High-speed Reciprocating Pillow Packaging Machine

- DWB-500H High-speed Reciprocating Pillow Packaging Machine

- HTZ-350S/450S High speed pillow packing machine

- DZB-250D/400D multi-functional pillow section automatic packaging machine

- DZB-250D Multifunctional Pillow-Type Automatic Packing Machine

Fully Automatic Cartoning Machine

Fully Automatic Cartoning Machine

High Speed Transparent Film Three-dimensional Wrapping Machine

High Speed Transparent Film Three-dimensional Wrapping Machine

Horizontal Automatic More Usage Packing Machine

The Speciality Manufacturer of Medical Supplies Packing Machine

Auxiliary device

Auxiliary device

Production line packaging

Production line packaging

DPH-260H Blister packaging machine collected flat plate type forming and roller sealing as incorporator. It applies to medicine packaging, such as variety specification of sugar coated or uncoated tablet, capsule, soft gel, injection and so on. It's also suitable for packing small hardware, electronical element, medical devices and foods which shapes are similar with above pharmaceuticals.

-

1.High speed, high stability and high accuracy when machine running.

-

2.Width of PVC and PTP both are 260mm, which designing is more humanized.

-

3.Flat plate is front pressure to form, roller plate type to seal, thus making the grid pattern more beautiful.

-

4.It can be equipped with universal feeding system or special pipeline feeding system according to the shape of medicines.

-

5.PLC human-machine interface control system to operate, stepless frequency inverter to main transmission. Each station adopts an independent worm gear reducer and link universal coupling device.

-

6.The cutting frequency is up to 40-160 blister plates/minute (the speed is adjustable according to the format length).

-

7.Printing batch numbers and expiry date, and plate impressing adopts plate drawing type handy replacement structure.

-

8.Lengthen filling platform which can improve yield and easy to be equipped with camera detection, automatic eliminate convey system, and conveyor link to automatic carton packing machine.

-

9.Cross cutting (borderless cutting) will not waste packing materials. This blister machine can save packing materials about 10%.

|

Cutting frequency |

40-200 times/minute |

|

Max.forming area |

250×250mm |

|

Max.forming depth |

12mm |

|

Travel adjusting |

150-250mm |

|

Size of standard plate |

80×57mm |

|

Width and thickness of PVC and PTP |

PVC:260×0.15-0.30mm PTP:260×0.02-0.03mm |

|

Power supply |

380V 50HZ, main motor:2.2KW heating:15KW |

|

Air Capacity |

≥0.5m3/min |

|

Cooling water |

Tap water or cycling water:60L/H |

|

Overall size |

4350×1070×2200mm |

|

Weight |

3000kg |

Words and photographs on this catalogues are to help understanding of the machine model only and subject totechnical modification without prior notice.The final specification is as per our quotation offered to youreself exclusively.