Blister Packaging Machine Series

Blister Packaging Machine Series

- DPP-260 Flat-plate Blister Packing Machine

- DPH-260 Roll-plate Blister Packaging Machine

- DPR-320G aluminum-plastic-aluminum equipment

- DPH-400H Roller Plate Blister Packaging Machine

- DPH-260L Roller Plate Blister Packaging Machine

- DPH-400K roller plate blister packaging machine

- DPH-260L roller plate blister packaging machine

- DPP-260 Flat-plate Blister Packing Machine

Pillow-type Packing Machine Series

Pillow-type Packing Machine Series

- DZB-250D Multifunctional Pillow-Type Automatic Packing Machine

- DWB-500 Reciprocating Pillow-Type Packaging Machine

- DWB-500G High Speed Reciprocating Pillow Type Packing Machine

- DWB-500K High Speed Reciprocating Pillow Type Packing Machine

- DZB-250/400 Multifunctional Pillow Block Fully Automatic Packaging Machine

- DWB-250C/400C/600C多功能枕式版塊全自動(dòng)包裝機(jī)

- DWB-500H High-speed Reciprocating Pillow Packaging Machine

- DWB-500H High-speed Reciprocating Pillow Packaging Machine

- HTZ-350S/450S High speed pillow packing machine

- DZB-250D/400D multi-functional pillow section automatic packaging machine

- DZB-250D Multifunctional Pillow-Type Automatic Packing Machine

Fully Automatic Cartoning Machine

Fully Automatic Cartoning Machine

High Speed Transparent Film Three-dimensional Wrapping Machine

High Speed Transparent Film Three-dimensional Wrapping Machine

Horizontal Automatic More Usage Packing Machine

The Speciality Manufacturer of Medical Supplies Packing Machine

Auxiliary device

Auxiliary device

Production line packaging

Production line packaging

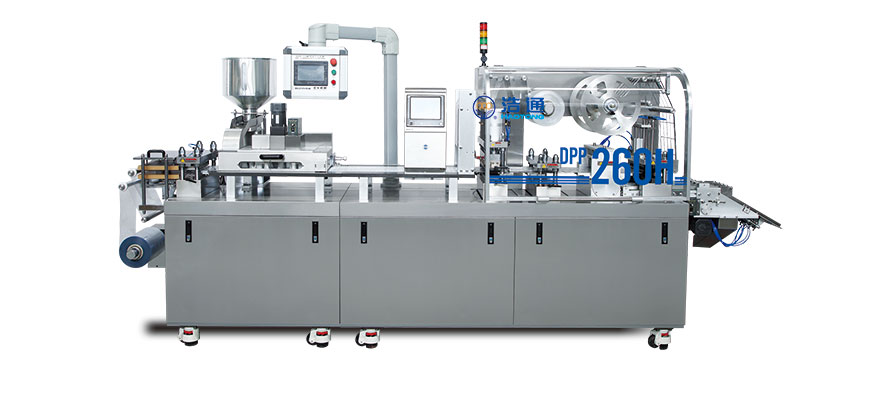

DPP-260H Flat-plate packaging machine collection light, machine, electricity, gas as incorporator, have PLC program control, servo traction, camera detecting, VS printing photoelectric, security cover, it can automatic accomplish forming, feeding, sealing, pressing, cutting etc, this machine suit for (AL/PVC, AL/AL, AL/AL/AL/) packing of pharmacy, foodstuff, electron, medicine treatment, metals goods.

|

Cutting Frequency |

20-240 plates/min |

|

Productivity |

18000-236000 pieces/h |

|

Max.forming area |

160×250mm |

|

Max.forming depth |

26mm |

|

Adjusting range of travel |

40-160mm |

|

Size of standard plate |

80×57mm |

|

Width and thickness of PVC and PTP |

PVC:260×0.15-0.45mm PTP:260×0.02-0.03mm |

|

Power supply |

380V 50Hz Main motorl1.5KW. Hot-sealing4.5KW |

|

Capacity of air compressor |

≥0.2m3/min |

|

Cooling of mold |

Tap water or cycling water, 60L/H |

|

Overall size |

3500×740×1680mm |

|

Weight |

2600kg |

Words and photographs on this catalogues are to help understanding of the machine model only and subject totechnical modification without prior notice.The final specification is as per our quotation offered to youreself exclusively.