This high speed combination Automatic production line, Having Aluminum-PVC and cartoning realize the flow integrated operation, reasonable structure, simple operation, improve the production efficiency and product qualification rate, reduce labor intensity and production cost, also can be connected with three-dimensional packing and heat shrink machine.

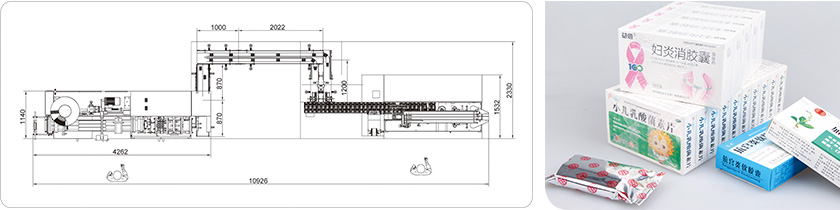

DPH260H-DXH300 Production line installation layout

|

Working pressure |

≥0.6mpa |

|

Air consumption |

20m3/h |

|

Power supply |

AC220V/50HZ |

|

Motor power |

8.65kw |

|

Aluminum-PVC |

Cutting frequency |

40-160 plates/min |

|

Max.forming size |

245×110mm |

|

|

Max.forming depth |

12mm |

|

|

Stroke adjusting |

150-250mm |

|

|

Size of standard blister |

80*57mm |

|

|

Width and thickness of PVC and PTP |

PVC:260×0.15-0.30mm PTP:260×0.02-0.03mm |

|

|

Power supply |

380V 50HZ 12KW |

|

|

Overall dimension |

4350×1070×2200mm |

|

|

Weight |

2000kg |

|

Cartoning |

Encasing speed |

80~300 boxes/min |

|

Quality requirement |

250-350g/m2 (according to its dimensions to confirm) |

|

|

Dimension range (L×W×H) |

(70-200) × (50-120) × (14-70)mm |

|

|

Quality requirement |

60-70g/m2 |

|

|

Unfolded leaflet specification |

(80-260)mm × (90-190)mm |

|

|

Folded leaflet specification |

1-4 Fold |

|

|

Machine dimension |

4600×1500×1750mm(L×W×H) |

|

|

Machine weight |

3200kg |

Note: The products of our company may always be updated, and are subject to change without notice (the real products shall prevail).